2K /two shots molding

- Home

- 2K /two shots molding

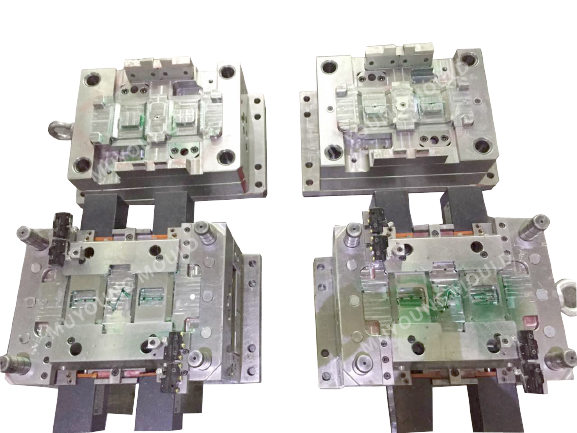

What is 2K molding / two-shots molding?

A 2K molding/two-color molding is a mold in which two different plastic materials or 2 colors are molded on the same injection molding machine, the product comes out of the mold only once. It is efficient and economical, and requires a special two-color injection molding machine. Using 2K technology can avoid possible manual assembly steps, cost advantages, design features or aesthetic preferences.

Basic principles of two-color injection mold amount and over molding design.

- First injection hard plastic material such as (ABS、AS (SAN)、PC、PC/ABS、PE、PP、PS(HIPS,GPPS)、MBS , soft rubber for second molding, such as TPE、TPR、silicon、PVC、TPU、TPV and TPEE, the models applied to handle parts, control buttons and anti-slip applications parts, etc. ……

- Transparent plastic material to do the first molding, non-transparent to do the second molding; the plastic part applied to such as electronic cigarettes.

- High temperature plastic material to do the first molding, and low temperature plastic material molding temperature to do the second molding.

What are the advantages of 2K molding/two shots molding?

1: Through 2K injection molding, you can inject the plastic into the mold at once or multiple times individually to make the product have precise integration between the materials, increase the comfort, sealing requirement for waterproofing, etc ….

2: Products injected by 2K molding/two shot molding can be injected with 2 colors that can be seamlessly combined together for a more attractive appearance.

3: Combining two components by 2K injection molding, injection molding is efficient and produces products at a lower cost.

4: compared with over molding injection molding, 2K mold has advantages for complex product design.

5: Compared with over molding / in the selection of plastic materials in a wider range, because 2K molding in the molding of the first molded product for the heating state for the second injection, allowing a greater range of plastic material selection molding to meet the product function.

What are disadvantages of 2K injection mold?

1: Compared with over molding, the investment of injection molding machine is higher, but 2K mold injection can save cost by eliminating the step of hand loading the first product to the second mold, which will pay for itself quickly if a large number of products are needed

2: Not all plastics can be injection molded with 2K, some plastics do not have enough adhesive force to allow effective fusion between products.

Muyoung a professional manufacturer of 2K molds and over molding, Muyoung will be happy to advise you on material selection and processing methods if you are not sure what option to choose, or you can use the over molding option to achieve your product needs; free quotes and DFM design view are available.