Quality Assurance

Certification

Quality Assurance

Muyoung is certified and compliant with ISO 9001:2015 and TS 16949; these ISO standards specify the management requirements for quality occupational health, safety and environment.

Quality Assurance

ISO certifications help us to achieve customer satisfaction,In order to ensure that no rework, we continue to improve our inspection process which including DFM, mold design, steel material, CNC processing, EDM processing and assembly.Here are inspection steps:

- DFM

- Mold design checking list

- Material inspection

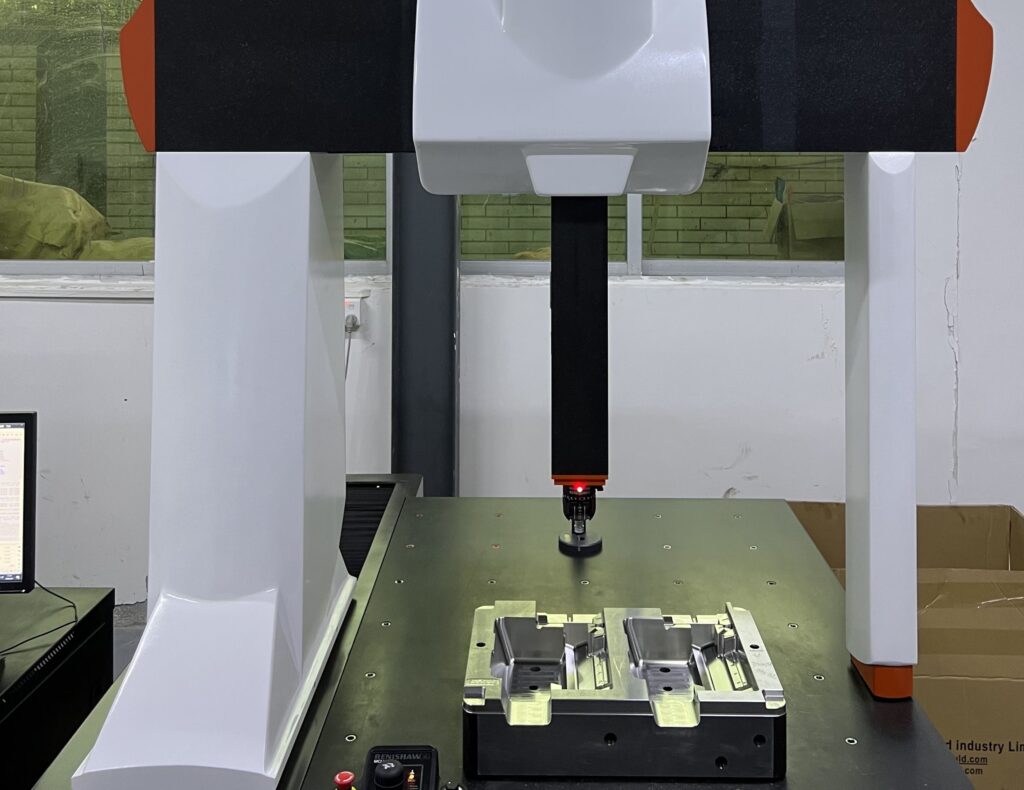

- Manufacture inspection (CNC Processing, EDM processing and assembly)

- Samples inspection

- Samples inspection

- Check mold according to the checking list before delivery

Let's raise your profits to next level Now→

Muyoung Mould will provide the following service when you send us your requiry.

Free DFM Feedback with Your Quote

Products Tolerance ±0.005mm

Full-automatic molding;

Low-Maintenance molds;

Modification price is reasonable;

Keep completive price;

Delivery Door to Door

Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “sales@mu-mould.com”.

Upload Your 3D Files

We accept the 3D model with file formats: STEP(.stp), IGES(.igs), PRT(.prt),X_T(.xt),STL(.stl),

2D drawing format: PDF、DWG、DXF, The maximum supported file size is 80MB, for large or multiple files, please place into folder and compress into a ZIP or RAF files.