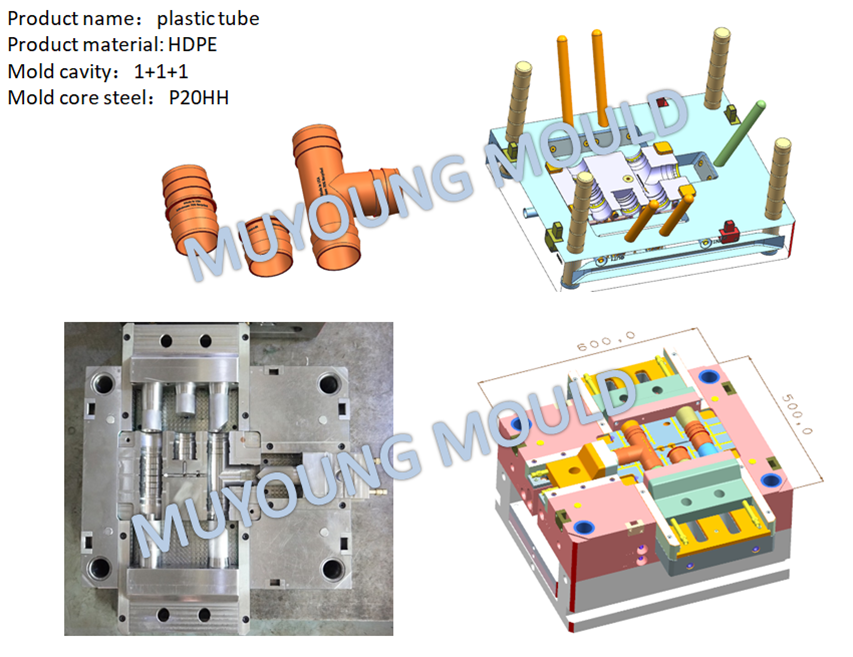

Family molds

- Home

- Family molds

What is a family mold?

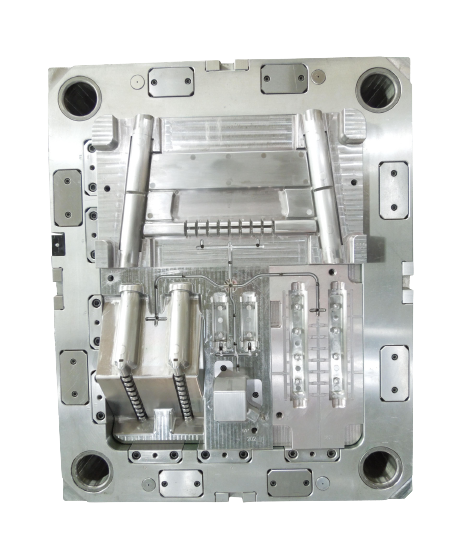

A “family mold” is a mold that is used to make several plastic products with different characteristics in one shot, each product in the mold will be of the same material and color or different materials or colors, and complex plastic product structures are also available .

Muyoung recommends the use of family molds for small to medium sized products and similar features, because whether using hot or cold runners, 2 or 3 plate molds, family molds have their own limitations.

- when molding several products with different characteristics at the same time, it is necessary to consider separating these products before packaging.

- When the number of certain products in the same set of molds needs to be more, this will waste the use of a larger injection molding machine to produce this product, resulting in waste.

Why should we use family molds?

1: To make the inlet switch in a family mold, you can control the production of any product with different characteristics, the number of products, or even different materials or colors.

2: family molds can greatly reduce the cost of molds, by injecting different characteristics of plastic products at one time.

3: family molds can mention manufacturing efficiency.

4: family mold injection molding products can be done precisely color matching color, in the characteristics of similar products without sub-batch color mixing resulting in subtle color

A common cause, a common struggle,

Mutual support and win-win cooperation

Jack Shan – CEO & Founder Muyoung mould industry LTD