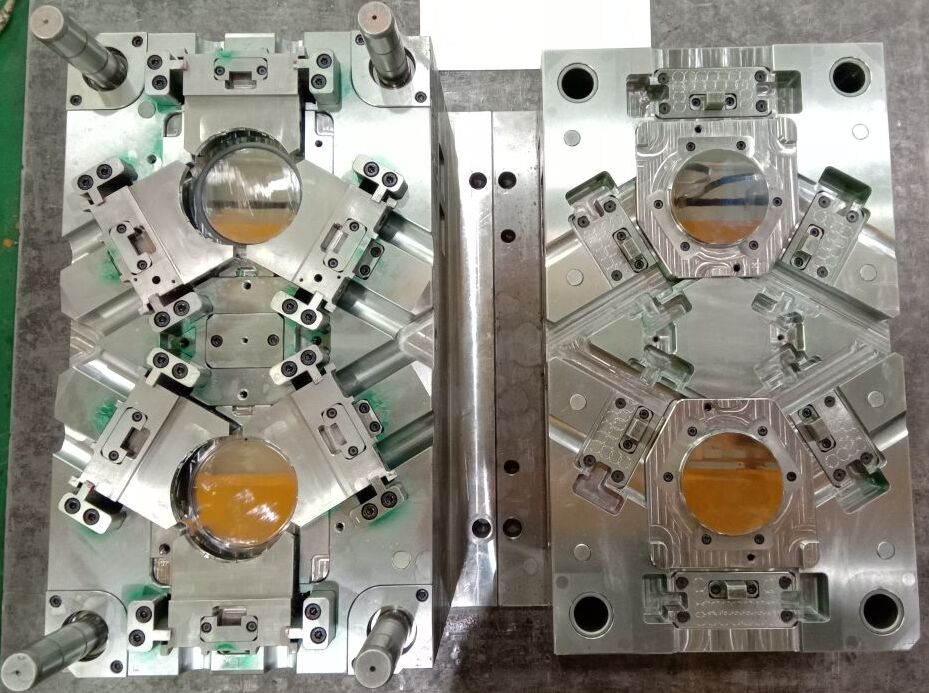

Mass production molds

- Home

- Mass production molds

Mass production molds

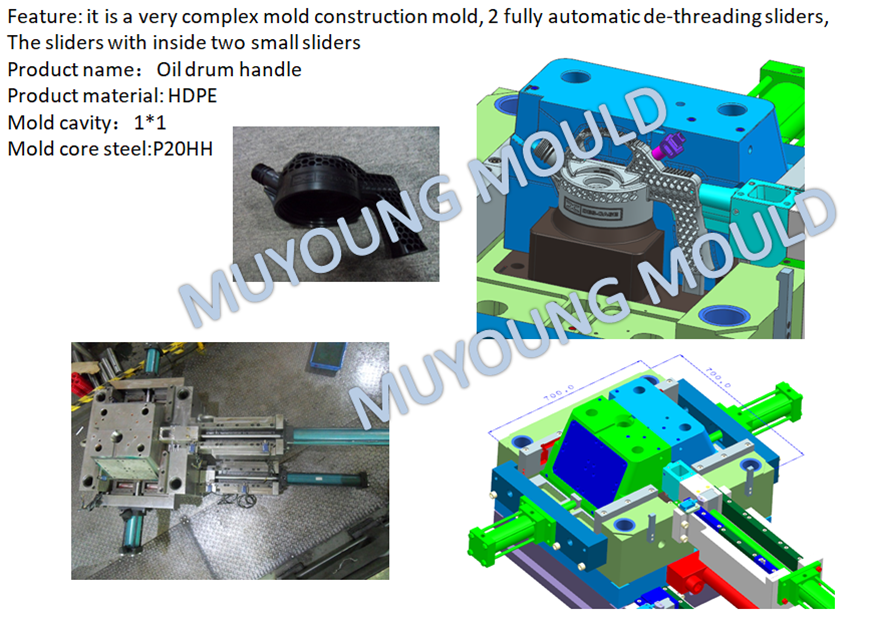

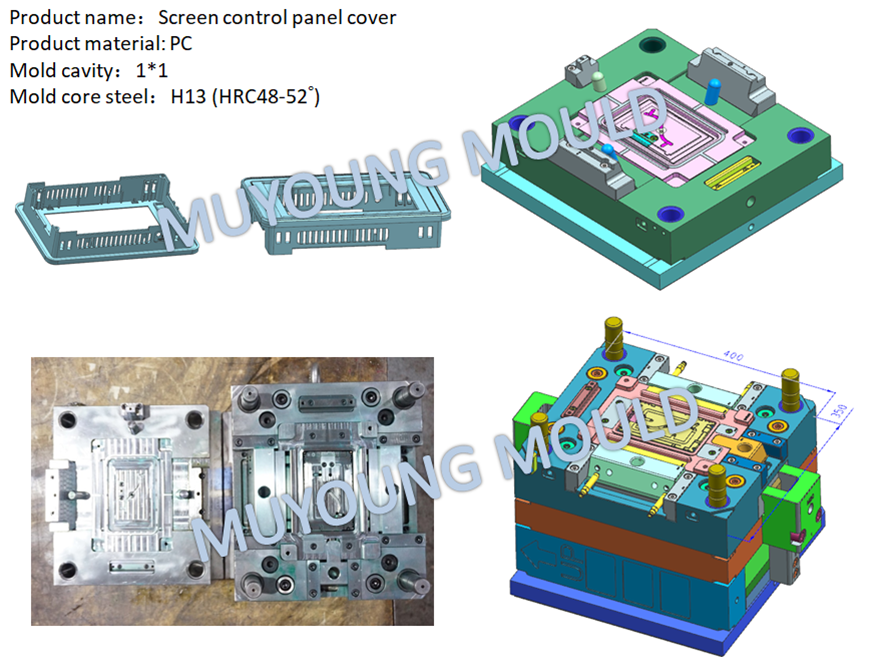

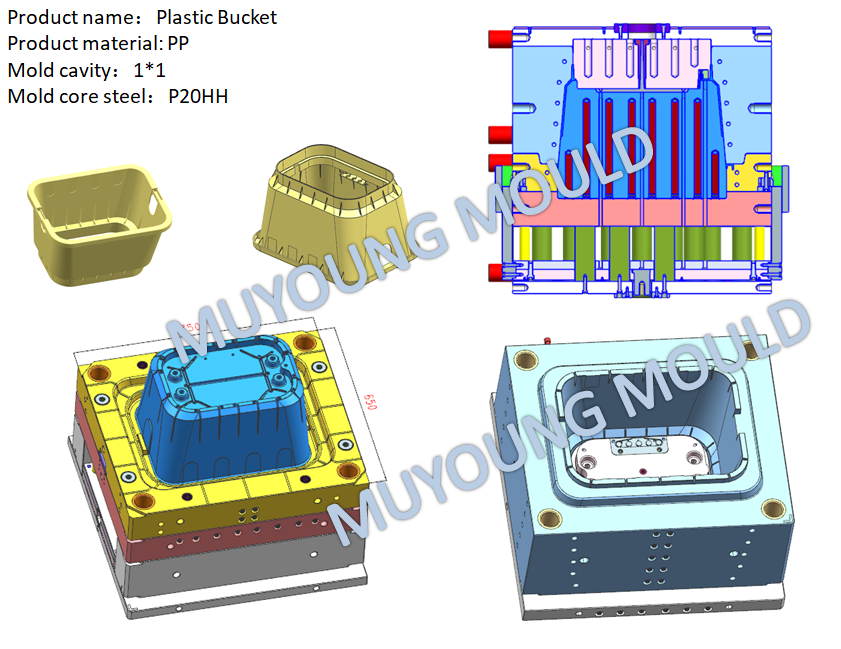

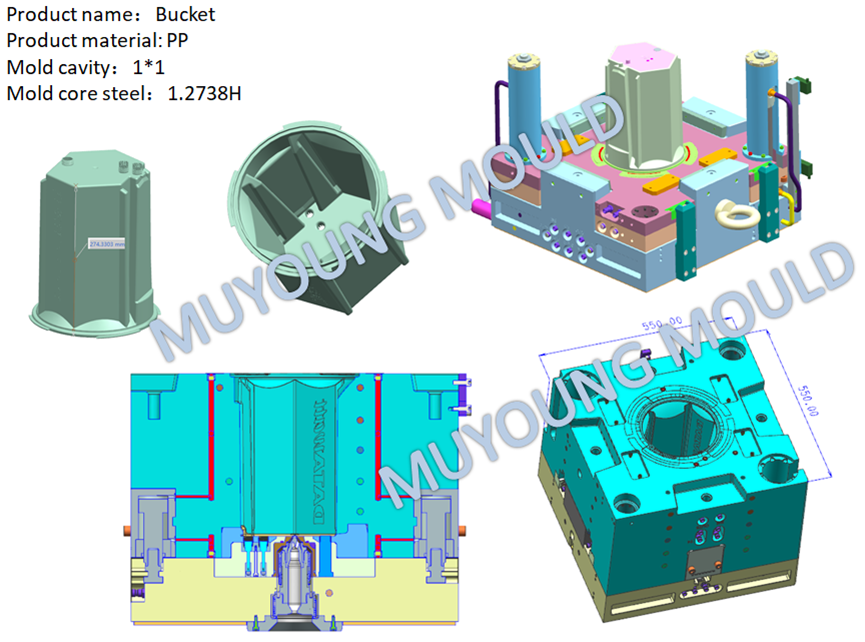

Muyoung has 20 years of experience in producing mass production injection molds and 80% of plastic injection molds are mass production injection molds, their mold-life is between 200,000 and 2 million.

We have produced injection molds required by different industries such as: automotive industry, forklift parts, electronic products, consumer goods, construction industry, agricultural machinery…… Whether it is a complex or simple plastic part structure, our engineers can find experience in producing 3000 projects to guarantee your project successfully.

Why choose Muyoung as your mass production mold supplier?

1: Short cycle time of injection molding, our experienced engineers design reasonable injection system and water cooling system and mold makers with advanced manufacturing process can shorten the cycle time of injection molding, the molds run more efficiently and the total cost is lower.

2: The mold can be produced for a long time, some molds need to produce 10 years or more, then you need to consider the maintenance of the mold, Muyoung in the design to consider the wear resistance of steel to avoid long-term friction after the gap, in the manufacturing process to choose advanced technology and the use of better mold components, we always make low maintenance mold to win the long-term cooperation of customers.

A common cause, a common struggle,

Mutual support and win-win cooperation

Jack Shan – CEO & Founder Muyoung mould industry LTD