Services

/*! elementor – v3.10.1 – 17-01-2023 */

.elementor-heading-title{padding:0;margin:0;line-height:1}.elementor-widget-heading .elementor-heading-title[class*=elementor-size-]>a{color:inherit;font-size:inherit;line-height:inherit}.elementor-widget-heading .elementor-heading-title.elementor-size-small{font-size:15px}.elementor-widget-heading .elementor-heading-title.elementor-size-medium{font-size:19px}.elementor-widget-heading .elementor-heading-title.elementor-size-large{font-size:29px}.elementor-widget-heading .elementor-heading-title.elementor-size-xl{font-size:39px}.elementor-widget-heading .elementor-heading-title.elementor-size-xxl{font-size:59px}

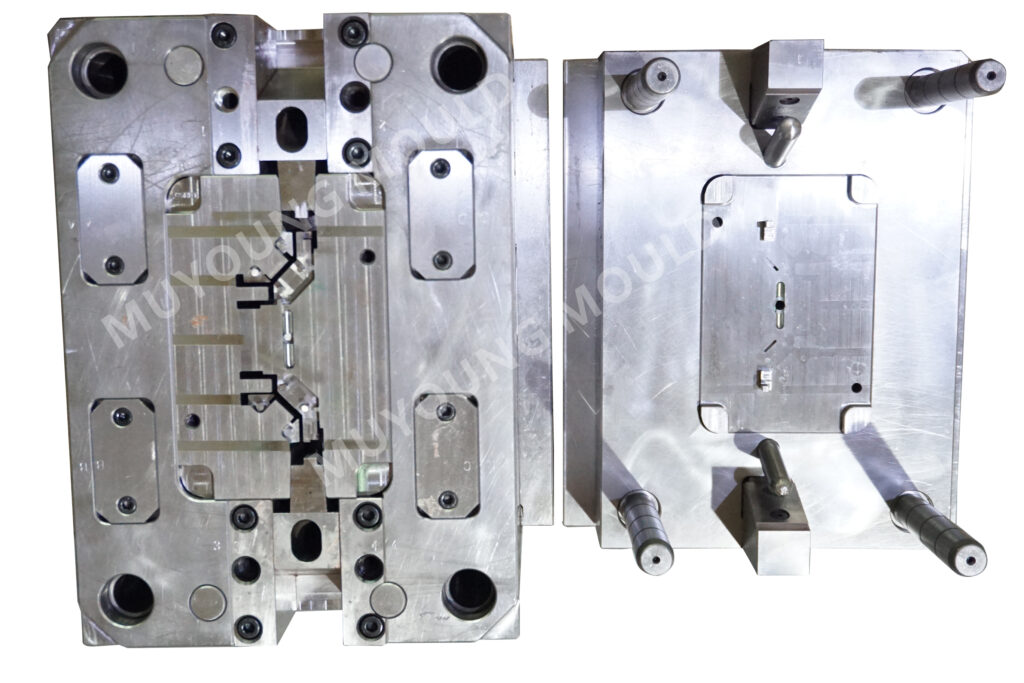

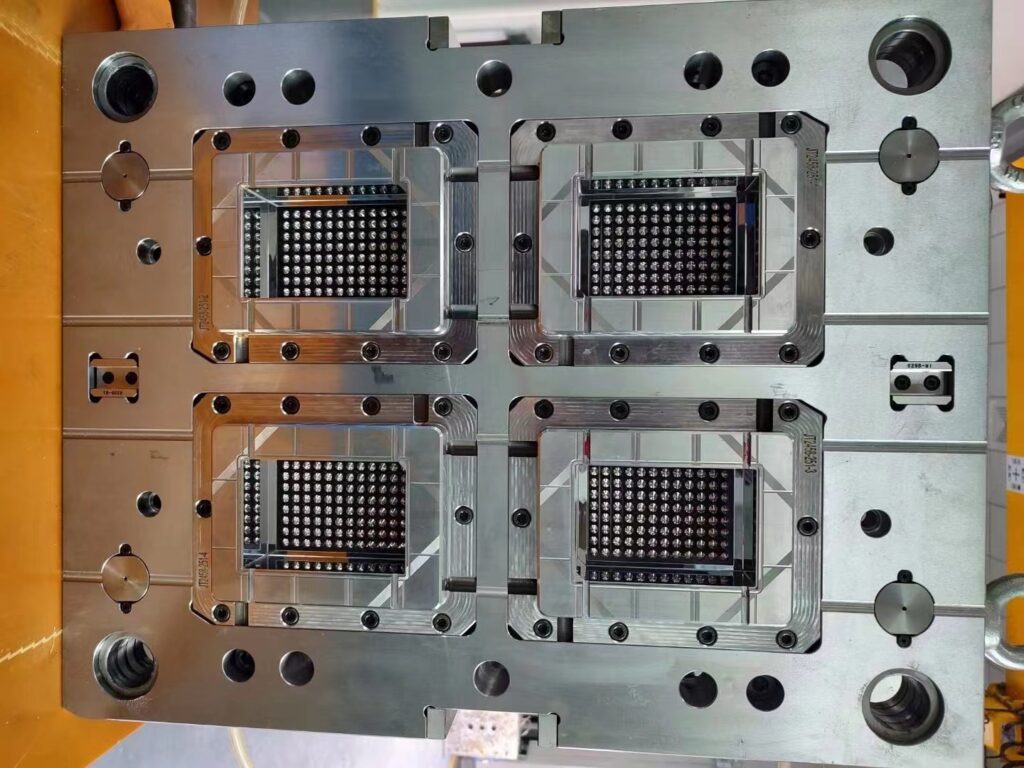

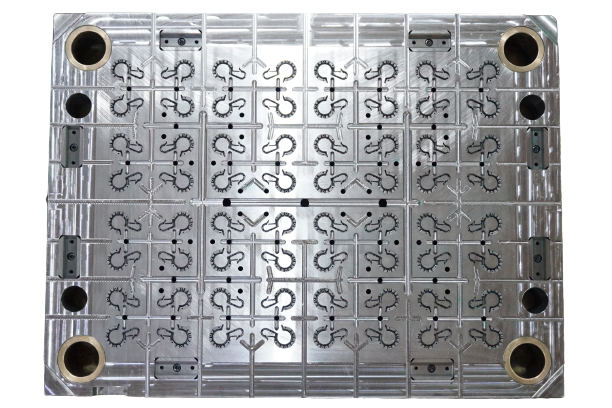

Plastic mold Manufacturer in China

- Free DFM Feedback with Your Quote

- Products Tolerance ±0.005 mm

- Low-Maintenance molds

- T1 samples AS Fast AS 2-3 Weeks

- Keeping Competitive Prices

- Modification Price is reasonable

- Global Door-to-Door Delivery

Get A Quickly Quotation Today

/*! elementor – v3.10.1 – 17-01-2023 */

.elementor-column .elementor-spacer-inner{height:var(–spacer-size)}.e-con{–container-widget-width:100%}.e-con-inner>.elementor-widget-spacer,.e-con>.elementor-widget-spacer{width:var(–container-widget-width,var(–spacer-size));–align-self:var(–container-widget-align-self,initial);–flex-shrink:0}.e-con-inner>.elementor-widget-spacer>.elementor-widget-container,.e-con-inner>.elementor-widget-spacer>.elementor-widget-container>.elementor-spacer,.e-con>.elementor-widget-spacer>.elementor-widget-container,.e-con>.elementor-widget-spacer>.elementor-widget-container>.elementor-spacer{height:100%}.e-con-inner>.elementor-widget-spacer>.elementor-widget-container>.elementor-spacer>.elementor-spacer-inner,.e-con>.elementor-widget-spacer>.elementor-widget-container>.elementor-spacer>.elementor-spacer-inner{height:var(–container-widget-height,var(–spacer-size))}

20

Years Experience

Need to Rapid tooling or mass produce plastic molded products?

When you need more than 500+ plastic products, you will need molds to make them for you, whether it is a small batch of Rapid tooling or a mass production of molds, Muyoung is one of the best plastic mold manufacturers in China, we provide our customers with low cost and high quality export molds through our advanced equipment and constantly optimized process.

- Plastic injection mold

- Die casting mold

- Silicone rubber mold

- BMC/DMC mold(Bulk (Dough) molding compounds)

- SMC mold(Sheet molding compound)

/*! elementor – v3.10.1 – 17-01-2023 */

.elementor-widget-image{text-align:center}.elementor-widget-image a{display:inline-block}.elementor-widget-image a img[src$=”.svg”]{width:48px}.elementor-widget-image img{vertical-align:middle;display:inline-block}

Rapid mold

Sometimes a client is not sure about a product design and will need prototypes of a product to validate this. Rapid mold construction is simplified and made quickly,and cost cheap.

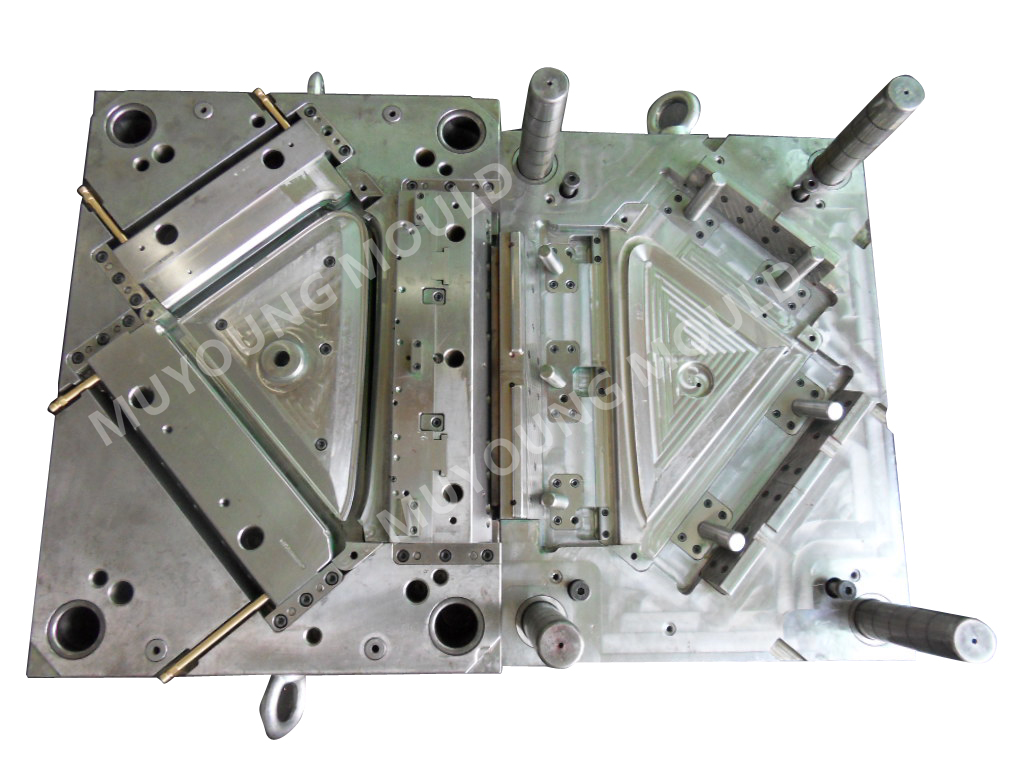

2 Plate/3 Plate Mold

This is the most common type of mould. It consist of 2 mould halves which open to release the product. Generally, the part is injected on the cavity side and ejected from the core side.

Hot runner mold

Plastic injection mold with hot runner systems produce less waste plastic, shorter molding cycles, lower energy consumption, higher gate quality, and require less labor for runner handling, trimming and regrinding.

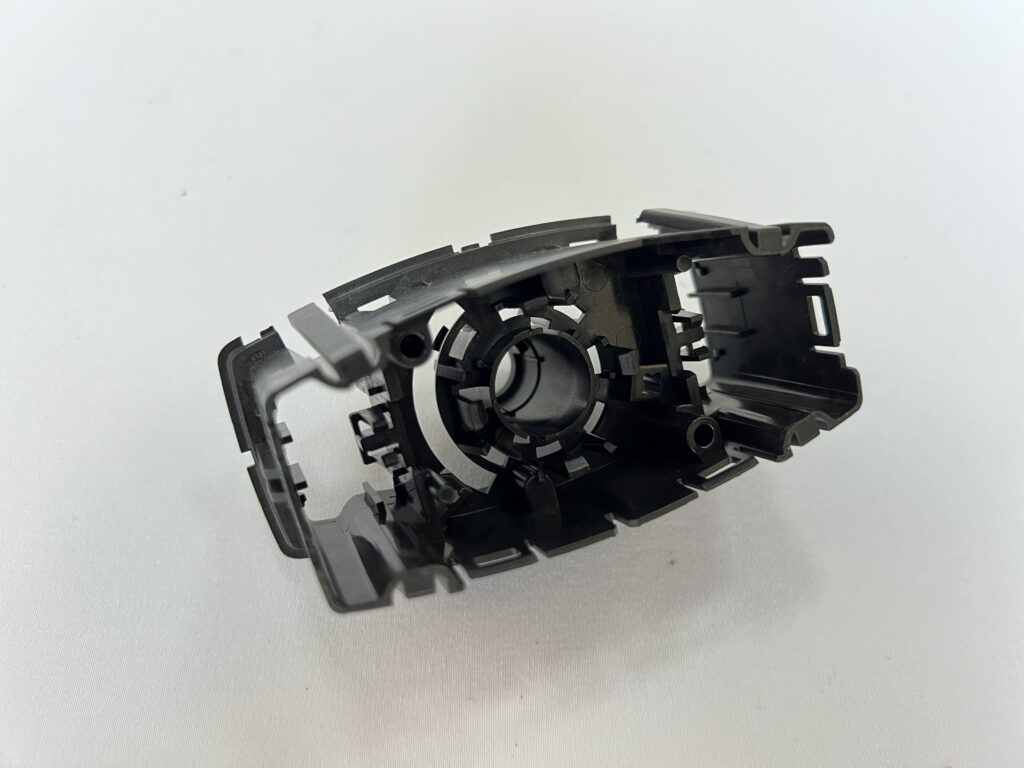

Insert mold

Some products need to have inserts moulded in them. Often these are metal bushes to add a thread in a product or other metal inserts.

2K mold

In this type of mould the product is made of 2 different kinds of plastic. In most cases this is a normal type of plastic combined with a certain TPE.

Unscrewing mold

Some products require an internal thread. To release this thread there needs to be a rotating spindle in the mould.

What are the advantages of our mould making services?

- Long term is our end game,

- We strive to understand your goals, innovation and customer focus are the basis of mutually beneficial partnerships,

- When challenged with difficult mold manufacture, Muyoung is able to create new idea, thereby reducing costs, Muyoung’s term understand how the injection mold needs to be created, our term is knowledgeable and easy to work with, and provide exceptional customer service, build high quality tool and flexible lead time, we are always competitive on price,

- Muyoung adapts very quickly to change, can do custom work and provide each client with the personal attention they deserve. Muyoung is willing to try everything to produce the results the client is looking for. We always are willing to take on a challenge,

- We promise our customers that we’ll do that competitively, without sacrificing quality,

- Muyoung has been works with a number of freight forwarders to help our customers find a competitively priced shipping method, DDP by air or DDP by sea.

Contact us today to get start!

Steps in the manufacture of injection moulds.

01

Mold Flow→DFM→3D Mold Design→2D Mold Design

02

Purchase Steel Material: Mold Base, Hot Runner, Mold Standard Components

03

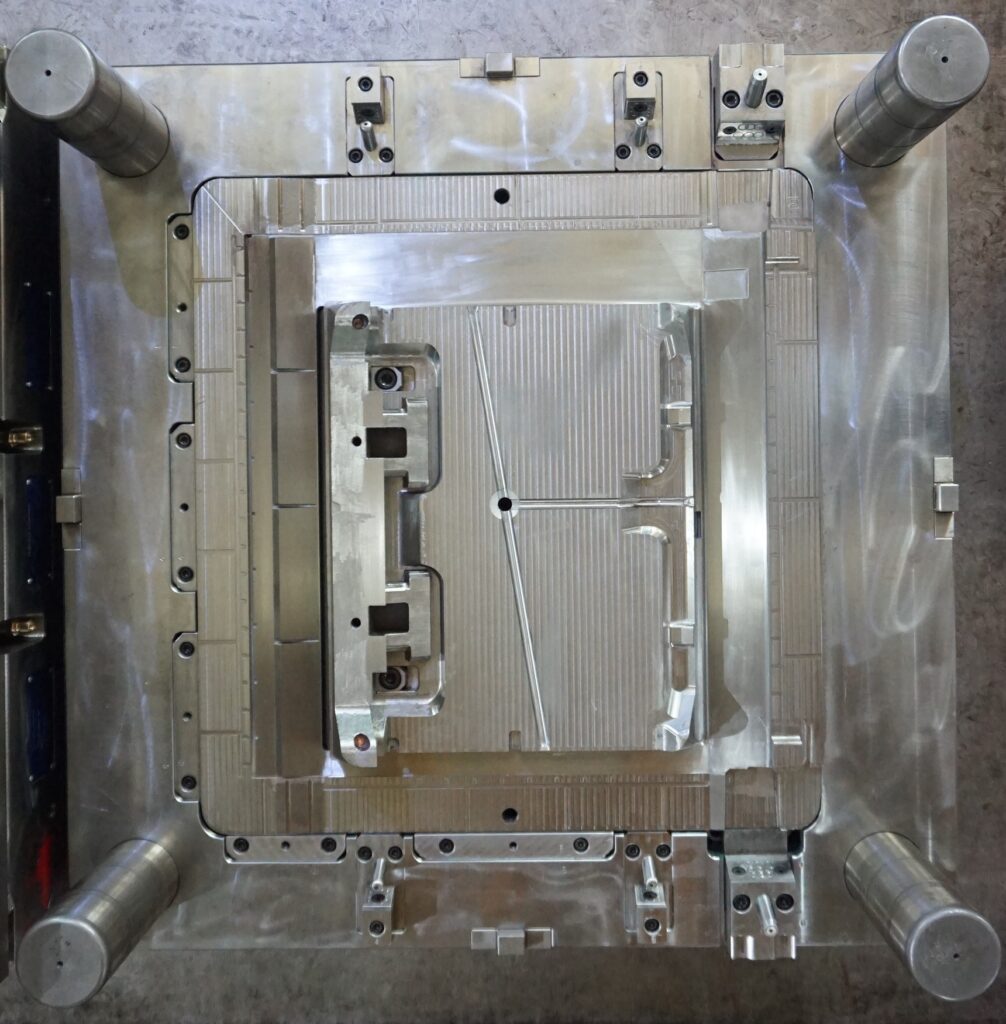

Machining: CNC Machining, EDM Machining, Drilling process, polishing, Assembly, Fitting

04

Mold Trial: Provide Mold Trial report, Measurement Report; Send T1 Samples

What kindly of mold base and components standard do we use?

We will use standard mold base and accessories according to the customer’s preference, the main standards are as follows

DME Stantard

HASCO Standard

LKM Standard

RABOURDI Standard

FUTABA Standard

How to select the right mold steel?

Choosing the right mold steel will be very important for plastic injection tooling quality, taking into account mold type, mold cost, mold life, plastic material, product surface requirements, steel wear and tear and other. Muyoung provides the steel material certification for per mold.

Automotive parts and molds

Electronic Machine

Householde /Package part

Medical product

Agricalture product

Consumer Product

Free DFM Feedback with Your Quote

Products Tolerance ±0.005mm

Full-automatic molding;

Low-Maintenance molds;

Modification price is reasonable;

Keep completive price;

Delivery Door to Door

Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “sales@mu-mould.com”.

Upload Your 3D Files

We accept the 3D model with file formats: STEP(.stp), IGES(.igs), PRT(.prt),X_T(.xt),STL(.stl),

2D drawing format: PDF、DWG、DXF, The maximum supported file size is 80MB, for large or multiple files, please place into folder and compress into a ZIP or RAF files.

Showing the single result